The Contact Clip, the Heart of the Mill-Max Receptacle

Reliable Connections Made Possible

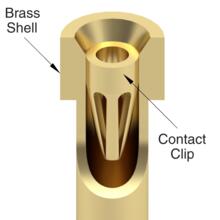

Mill-Max receptacles consist of a two-component construction that includes a precision machined outer shell and an internal contact clip. The internal contact clip is the center of the Mill-Max receptacle and provides reliable and consistent contact with mating component leads. The contact clip is a conductive, multi-finger, progressive die stamped design that engages with a range of mating pins to form a reliable mechanical and electrical connection. Mill-Max contacts are manufactured from either Beryllium Copper or Beryllium Nickel as these materials offer superior spring characteristics which allow forces to be applied against a mating lead. Contact clips, consist of 3, 4 or 6 fingers, which open and engage, score and apply holding force against the mating pin, forming an electrical and gas tight connection across multiple points of contact.

Pluggable Components Made Simple

These Pin Receptacles are the dynamic building blocks within an electrical interconnect system. Mill-Max currently offers an extensive range of contacts that will accept round leads ranging from .008” (0,203mm) to .102” (2,591mm) in diameter, as well as square and rectangular leads where the effective diameter is taken as a diagonal dimension. All Mill-Max receptacles are capable of a minimum of 1,000 insertion/extraction cycles for a broad range of applications.

Contact Clip Plating

Each component of the receptacle is plated separately prior to final assembly during manufacturing. This allows for gold plating on the internal contact clip which provides low and stable contact resistance along with superior protection against corrosion. Mill-Max offers receptacle shells plated with Gold, Tin/Lead or Matte Tin for ROHS requirements.

Contact Clip Interchangeability and Design Possibilities

A unique feature of the Mill-Max Receptacle is the ability to use different style contact clips inside the same receptacle shell. Most Mill-Max contact clips are characterized within a specific group code. By selecting a different contact clip that falls into the same group code one can change the effective current rating, temperature specifications, insertion/extraction force or depth of the initial contact point. Most standard receptacles can be easily configured and assembled by Mill-Max with alternative contacts to suit different application requirements.

Contact Clip Selector Chart

Shown below is a contact selector chart that has been organized by group code to help assist you in choosing the right contact for your application. Be sure to review our FAQ on Contact Clips and Receptacle Design for tips on what to consider in your design.

| Contact Group | Contact Number | Accepts Minimum Pin Diameter | Accepts Maximum Pin Diameter | Contact Compliancy | Contact Length | Number of Fingers | Contact Material* | Maximum Current** | Maximum Derated Current |

|---|---|---|---|---|---|---|---|---|---|

| None | 04 | .008" (0,203mm) | .013"(0,330mm) | .003" (0,076mm) | .053" (1,364mm) | 3 | BeCu | 5 Amps | 4 Amps |

| None | 10 | .012 (.305mm) | .017 (.432mm) | .002" (0,051mm) | .060" (1.524mm) | 6 | BeCu | 6 Amps | 4.8 Amps |

| A | 09 | .015 (.381mm) | .018 (.457mm) | .002" (0,051mm) | .051" (1.295mm) | 3 | BeCu | 9 Amps | 7.2 Amps |

| A | 11 | .015 (.381mm) | .020 (.381mm) | .003" (0,076mm) | .075" (1.905mm) | 3 | BeCu | 8 Amps | 6.4 Amps |

| A | 21 | .015 (.381mm) | .022 (.559mm) | .004" (0,102mm) | .075" (1.905mm) | 3 | BeCu | 6 Amps | 4.8 Amps |

| A | 31† | .018 (.457mm) | .023 (.584mm) | .004" (0,102mm) | .062" (1.575mm) | 4 | BeCu | 13 Amps | 10.4 Amps |

| A | 05 | .015 (.381mm) | .022 (.559mm) | .004" (0,102mm) | .075" (1.905mm) | 3 | BeCu | 7 Amps | 5.6 Amps |

| A | 25 | .015 (.381mm) | .020 (.508mm) | .003" (0,076mm) | .075" (1.905mm) | 3 | BeNi | 12 Amps | 9.6 Amps |

| B*** | 12 | .015 (.381mm) | .022 (.559mm) | .003" (0,076mm) | .062" (1.575mm) | 4 | BeCu | 11 Amps | 8.8 Amps |

| B*** | 22 | .015 (.381mm) | .022 (.559mm) | .005" (0,127mm) | .062" (1.575mm) | 6 | BeCu | 10 Amps | 8 Amps |

| C*** | 30 | .015 (.381mm) | .025 (.635mm) | .005" (0,127mm) | .083" (2.108mm) | 4 | BeCu | 12 Amps | 9.6 Amps |

| C*** | 38 | .015 (.381mm) | .025 (.635mm) | .004" (0,102mm) | .083" (2.108mm) | 4 | BeNi | 12 Amps | 9.6 Amps |

| C*** | 32 | .015 (.381mm) | .026 (.660mm) | .009" (0,229mm) | .083" (2.108mm) | 6 | BeCu | 8 Amps | 6.4 Amps |

| C*** | 35 | .015 (.381mm) | .026 (.660mm) | .008" (0,203mm) | .083" (2.108mm) | 6 | BeCu | 8 Amps | 6.4 Amps |

| C*** | 43 | .015 (.381mm) | .026 (.660mm) | .008" (0,203mm) | .083" (2.108mm) | 6 | BeCu | 8 Amps | 6.4 Amps |

| K | 15 | .020 (.508mm) | .032 (.813mm) | .005" (0,127mm) | .084" (2.134mm) | 6 | BeCu | 12 Amps | 9.6 Amps |

| K | 19 | .020 (.508mm) | .032 (.813mm) | .003" (0,076mm) | .084" (2.134mm) | 6 | BeCu | 12 Amps | 9.6 Amps |

| D | 06 | .022 (.559mm) | .032 (.813mm) | .007" (0,178mm) | .113" (2.870mm) | 4 | BeCu | 16 Amps | 12.8 Amps |

| D | 26 | .022 (.559mm) | .032 (.813mm) | .005" (0,127mm) | .113" (2.870mm) | 4 | BeNi | 16 Amps | 12.8 Amps |

| D | 16 | .022 (.559mm) | .034 (.864mm) | .006" (0,152mm) | .083" (2.108mm) | 6 | BeCu | 16 Amps | 12.8 Amps |

| D | 47 | .025 (.635mm) | .037 (.940mm) | .011" (0,279mm) | .083" (2.108mm) | 6 | BeCu | 15 Amps | 12 Amps |

| D | 56 | .025 (.635mm) | .037 (.940mm) | .009" (0,229mm) | .083" (2.108mm) | 6 | BeNi | 14 Amps | 11 Amps |

| L | 18 | .037 (.940mm) | .043 (1.092mm) | .004" (0,102mm) | .064" (1.626mm) | 6 | BeCu | 12 Amps | 9.6 Amps |

| L | 58 | .037 (.940mm) | .043 (1.092mm) | .003" (0,076mm) | .064" (1.626mm) | 6 | BeNi | 12 Amps | 9.6 Amps |

| E | 36 | .022 (.559mm) | .042 (1.067mm) | .022" (0,559mm) | .120" (3.048mm) | 4 | BeCu | 16 Amps | 12.8 Amps |

| E | 34 | .032 (.813mm) | .046 (1.067mm) | .010" (0,254mm) | .120" (3.048mm) | 4 | BeCu | 17 Amps | 13.6 Amps |

| E | 49 | .032 (.813mm) | .046 (1.168mm) | .006" (0,152mm) | .125 (3.175mm) | 4 | BeCu | 15 Amps | 12 Amps |

| E | 24 | .032 (.813mm) | .046 (1.168mm) | .009" (0,229mm) | .120" (3.048mm) | 4 | BeNi | 16 Amps | 12.8 Amps |

| None | 48 | .037 (.940mm) | .043 (1.092mm) | TBD | .092" (2.337mm) | 4 | BeCu | 25 Amps | 20 Amps |

| F | 02 | .040 (1.016mm) | .050 (1.27mm) | .006" (0,152mm) | .088" (2.235mm) | 6 | BeCu | 16 Amps | 12.8 Amps |

| F | 28 | .042 (1.067mm) | .052 (1.321mm) | .005" (0,127mm) | .088" (2.235mm) | 6 | BeCu | 16 Amps | 12.8 Amps |

| J | 42 | .059 (1.499mm) | .063 (1.600mm) | .004" (0,102mm) | .150" (3.81mm) | 4 | BeCu | 24 Amps | 19.2 Amps |

| J | 03 | .040 (1.016mm) | .060 (1.524mm) | .010" (0,254mm) | .150" (3.81mm) | 4 | BeCu | 18 Amps | 14.4 Amps |

| G | 23 | .045 (1.143mm) | .065 (1.651mm) | .008" (0,203mm) | .100" (2.54mm) | 6 | BeCu | 18 Amps | 14.4 Amps |

| G | 13 | .048 (1.219mm) | .064 (1.626mm) | .010" (0,254mm) | .127" (3.226mm) | 4 | BeCu | 19 Amps | 15.2 Amps |

| G | 33 | .048 (1.219mm) | .064 (1.626mm) | .008" (0,203mm) | .127" (3.226mm) | 4 | BeNi | 19 Amps | 15.2 Amps |

| H | 07 | .065 (1.651mm) | .082 (2.083mm) | .013" (0,330mm) | .150" (3.81mm) | 4 | BeCu | 26 Amps | 20.8 Amps |

| H | 27 | .065 (1.651mm) | .082 (2.083mm) | .012" (0,305mm) | .150" (3.81mm) | 4 | BeNi | 30 Amps | 24 Amps |

| H | 14 | .065 (1.651mm) | .085 (2.159mm) | .014" (0,102mm) | .150" (3.81mm) | 4 | BeCu | 27 Amps | 21.6 Amps |

| None | 08 | .084 (2.134mm) | .102 (2.591mm) | .011" (0,279mm) | .122" (3.099mm) | 6 | BeCu | 30 Amps | 24 Amps |

* The standard material of contact clips is beryllium copper 172 which is suitable for applications operating in a constant temperature environment under 150° C. For applications operating in a temperature over 150° C we offer select clips in beryllium nickel. Both materials are heat treated to achieve optimal spring characteristics & durability.

** The current rating of a contact clip is a function of its material thickness and pin engagement surface area. Note, this current rating (for a 30° C temperature rise above ambient) is conservative since it rates an individual pin/receptacle pair in the free air. For all practical applications, the current rating will be higher because of the heat sinking ability of wires and circuit traces attached to the pin and receptacles and will depend on the specific application.

*** Group B and C contacts may be interchanged. However, receptacle shell hole depth must be considered when replacing a group B contact with a group C as the group C contacts are longer. Contact an Application Engineer to determine if the exchange will work.

†The #31 contact clip cannot be assembled into all group A receptacle shells. Contact an Application Engineer for further assistance.

For more information on contact range, and proper design of pin length and diameter, read on for more.