FR-4 Connectors, Ideal for Prototypes and Low-Volume Production

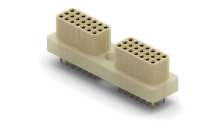

With respect to prototype and low volume connector requirements, it is often difficult to avoid costly Non-Recurring Engineering (NRE) charges up-front. However, Mill-Max Mfg. Corp. can provide custom, low-quantity connectors while avoiding tooling costs thanks to our in-house, FR-4 Epoxy milling capabilities. As well as injection-molded connectors for high-runs, Mill-Max utilizes glass filled epoxy material to provide custom-designed connectors tailored to meet your needs at low volume.

Mill-Max has the unique ability to create these connectors as many of our standard machined components incorporate a press-fit feature, making them suitable for assembly into FR-4 material. This makes batch production simple and quick, as we often have the machined components on the shelf.

Benefits

Designing a custom FR-4 connector is an extremely fast way to translate design concept into a tangible product. We understand that speedy turnaround times are crucial in today’s competitive market, and a quick prototype build can put you ahead of the game.

A custom FR-4 connector also adds convenience to your PCB assembly process. It can overcome production difficulties by incorporating all required contacts into a ‘one-piece’ substrate for simple board placement. The substrate also holds the parts in place during the soldering process. This is especially important for surface mount components using pin-in-paste techniques. The risk of parts ‘floating’ on the board is greatly reduced when using a connector. for placement.

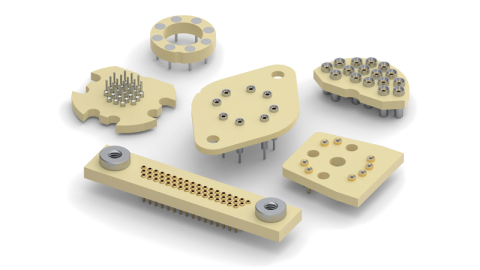

Customization

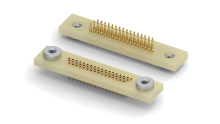

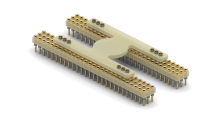

Our ability to mill and machine FR-4 allows the customer to create an interconnect to match the footprint of virtually any component, no matter how obscure the configuration or pin spacing. With near limitless milling capabilities in the x and y axes and extremely tight positional tolerances, we can custom design a connector to many shapes and sizes, even accommodating very fine pitch connector requirements.

Mill-Max can also ‘mix-and-match’ different machined components into the same FR-4 connector. Whether you need to socket a wide range of lead sizes or incorporate alignment pins for thru-hole stability, Mill-Max can unite these different components into one assembly. As well as machined components, Mill-Max can also add other components to the connector such as threaded inserts for fastening purposes.

FR-4 also allows Mill-Max to create unique ‘carrier’ products that enable multiple pins or receptacles to be deposited onto a board in one action, soldered and then removed.

Materials

With material thickness available from .010" -.500” we are sure to have an option that fits your requirement. For applications where exposure to high temperature environments is expected (beyond the capabilities of FR-4), we offer G-30 Polyimide/Glass Laminate material, suitable for higher temperatures.

Suitable for all ROHS soldering profiles, low volume FR-4 connectors from Mill-Max may be a perfect solution for you next prototype or low-volume production requirement. Contact us with your custom application to start the process.