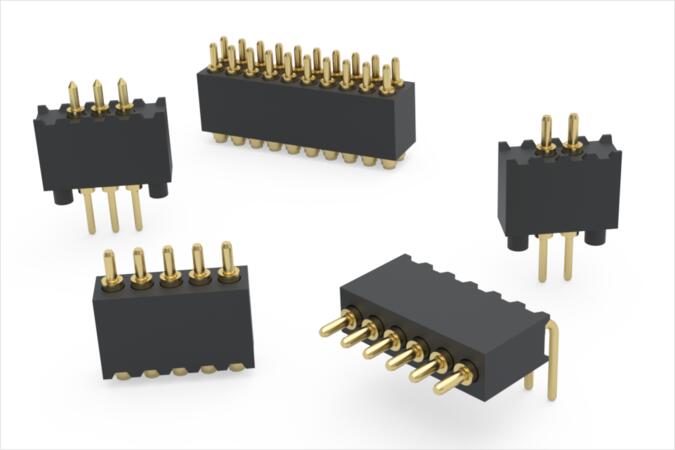

.050” Pitch Spring-Loaded Connectors with New Plunger Tip Options

Compact spring-loaded connectors with flat or pointed plunger tips for a variety of applications

Mill-Max expands our .050” (1.27 mm) pitch spring-loaded connectors, now available with either pointed or flat tip plungers. These new connectors add to our extensive offering of spring-loaded products, providing solutions for making optimal connections across a range of applications.

The new 854 (Single row) and 855 (Double row) series join the .100” (2.54 mm) pitch versions released last year to increase the choices available for your interconnect needs. The standard full radius plunger tip, found on most spring-loaded pins, is suitable for use in many cases, however, there are situations in which a different plunger tip shape can be advantageous. Flat tip plungers provide greater surface area at the point of connection, distributing the electrical charge and delivering more efficient heat dissipation. Typically, finer pitch connectors are used in compact assemblies and these improvements in heat management can reduce the total amount of heat generated in a circuit. Another advantage provided by flat tip plungers is they allow for greater tolerance misalignment of mating surfaces. Flat tip plungers provide consistent contact during lateral movement of the mating components because the larger pin tip surface stays in contact through a greater range of motion than a round tip. This can be vital in applications that are subject to motion and vibration, such as wearable devices for medical purposes. Lastly, they can be a good solution for situations where a designer has no control over the mating component and the spring pin tip must contact something other than a flat surface, such as a component lead. The pointed tip plunger design is often used with spring-loaded pins in test environments. The point design concentrates the force, creating greater pressure to penetrate oxides or other contaminants on the surface of the test unit, thereby providing a high-quality, low resistance connection. Another use for pointed tip plungers is for probing or contacting holes on printed circuit boards. The point provides a more suitable fit than a radius and can be used in a variety of hole sizes.

Both flat and pointed tip connectors are available in a variety of configurations including surface mount, thru-hole and right-angle terminations. Each pin is made with precision machined components and beryllium copper springs, all gold plated to ensure the highest conductivity, corrosion resistance and durability. They meet all the electrical, mechanical, and environmental specifications of their equivalent full radius style pins. The insulators are all high temperature rated, suitable for most soldering operations. Complete performance specifications and technical details can be found on our website. See the table below for part numbers and check our website for updates as we continue to add new versions.

Part Number | Plunger Tip Style (T) | Termination Style | Number of Rows | Number of Positions (0XX) |

4 = Flat 5 = Pointed

| Thru-hole | Single | 002 - 020 | |

Thru-hole | Single | 002 - 020 | ||

Right-angle | Single | 001 - 020 | ||

Right-angle | Single | 001 - 020 | ||

SMT | Single | 002 - 020 | ||

SMT | Single | 002 - 020 | ||

Thru-hole | Double | 004 – 040 | ||

Thru-hole | Double | 004 – 040 | ||

SMT | Double | 004 - 040 | ||

SMT | Double | 004 - 040 |

Need technical help or looking for a custom design? Use the form below to contact Mill-Max Technical Services.